- Group websites

- Knauf Insulation worldwide

- Corporate

- Albania

- Algeria

- Australia

- Austria

- Belgium

- Bosnia

- Bulgaria

- Canada

- Croatia

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Italy

- Japan

- Kazakhstan

- Latvia

- Lithuania

- Luxembourg

- Macedonia

- Malaysia

- Mexico

- Montenegro

- Morocco

- Netherlands

- New Zealand

- Norway

- OEM

- Poland

- Portugal

- Romania

- Russia

- Serbia

- Singapore

- Slovakia

- Slovenia

- South Africa

- South Korea

- Spain

- Sweden

- Switzerland

- Tunisia

- Turkey

- UAE

- USA

- Ukraine

- United Kingdom

- Knauf Insulation worldwide

- Group websites

- Knauf Insulation worldwide

- Corporate

- Albania

- Algeria

- Australia

- Austria

- Belgium

- Bosnia

- Bulgaria

- Canada

- Croatia

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Italy

- Japan

- Kazakhstan

- Latvia

- Lithuania

- Luxembourg

- Macedonia

- Malaysia

- Mexico

- Montenegro

- Morocco

- Netherlands

- New Zealand

- Norway

- OEM

- Poland

- Portugal

- Romania

- Russia

- Serbia

- Singapore

- Slovakia

- Slovenia

- South Africa

- South Korea

- Spain

- Sweden

- Switzerland

- Tunisia

- Turkey

- UAE

- USA

- Ukraine

- United Kingdom

- Knauf Insulation worldwide

- Home

- The future of our planet isn’t set - let's help it with right insulation solutions

The future of our planet isn’t set - let's help it with right insulation solutions

It is in our hands. At Knauf Insulation we accepted this responsibility many years ago, and even though it seemed an impossible endeavour at first, it took us on a journey of continuous improvement. The result here is not only environmental. Embedding sustainability in our company’s DNA has made us more competitive on the insulation market. Our products save energy, cut emissions and are designed to make sure buildings and applications are good for the environment and keep people healthy, safe and well.

Mineral Wool insulation with ECOSE® technology, which shook the market over a decade ago, and many other improvements in our products and production processes were developed with exactly this responsibility in mind. Today our business partners and clients expect us to be always one step ahead when it comes to sustainability. We are doing everything in our power to deliver on their expectations, because we want to play our part in creating a healthier and happier future for our planet for everybody.

But sustainability is a process of continuous improvement.

Over the past decade, we have achieved great things and we are proud of how we have changed our company, helped our colleagues, communities and customers, and reduced our impact on the environment. But we need to build on our successes even further – we must do more for our people and our environment. This is why we have created our new sustainability strategy, called ‘For A Better World’ because it builds on the success of our mission statement: “Our vision is to lead the change in smarter insulation solutions for a better world.”

We have set ourselves four important long-term goals for the future.

We firmly believe that our current leadership should be held accountable for making progress against these four goals. We must not leave the problem for the next generation to deal with.

Deliver a circular economy – how we do more with less

Most people today know that upcycling isn’t cycling up the hill. It is the use of waste materials in a way that results in a product with greater value or performance than the input material. This is exactly what we are doing by using recycled glass to produce high-quality glass mineral wool.

Our Glass Mineral Wool with ECOSE® Technology is composed of up to 80% recycled glass, and the remaining content mainly derives from rapidly renewable materials. We are committed to using more than 65% external recycled material for all our Glass Mineral Wool products by 2025.

The more recycled glass we use, the better. High levels of recycled material save huge amounts of manufacturing energy, compared to processing virgin raw materials, and that means saving more emissions and reducing the embodied carbon of our products.

The more recycled glass we use, the better. High levels of recycled material save huge amounts of manufacturing energy, compared to processing virgin raw materials, and that means saving more emissions and reducing the embodied carbon of our products.

Simply by using recycled glass we have reduced the use of raw materials/natural resources and reduced the amount of manufacturing energy. Optimisations like this bring encouraging results. Since 2010 we have reduced energy use by 22.7% and related emissions by 23.2%. In this same period we have reduced the use of water by 39.8% and water discharge by 80.7%, and cut the waste to landfill by 67.3%.

During a 50-year lifecycle, Mineral Wool with ECOSE® Technology will typically save more than 500 times the energy that was used to manufacture it.

Let's keep it green

Our Mineral Wool with ECOSE® Technology has proven its qualities and performance again and again. Installers favour it because it is pleasant to handle, and homeowners choose it because it contains no added formaldehyde, artificial dyes or acrylics. It was awarded Eurofins' first Indoor Air Comfort Gold certificate for indoor air quality, but it is the general recognition of building and industry experts that ECOSE is a better and more environmentally friendly choice that makes us really proud.

We’re committed to providing the market with the information it needs to be able to properly assess the environmental impact of our products. In assessing the sustainability of our products, we examine every stage of a product’s life-cycle in minute detail, from cradle to grave, through Life Cycle Assessment. This information is then processed and published as our Environmental Product Declarations.

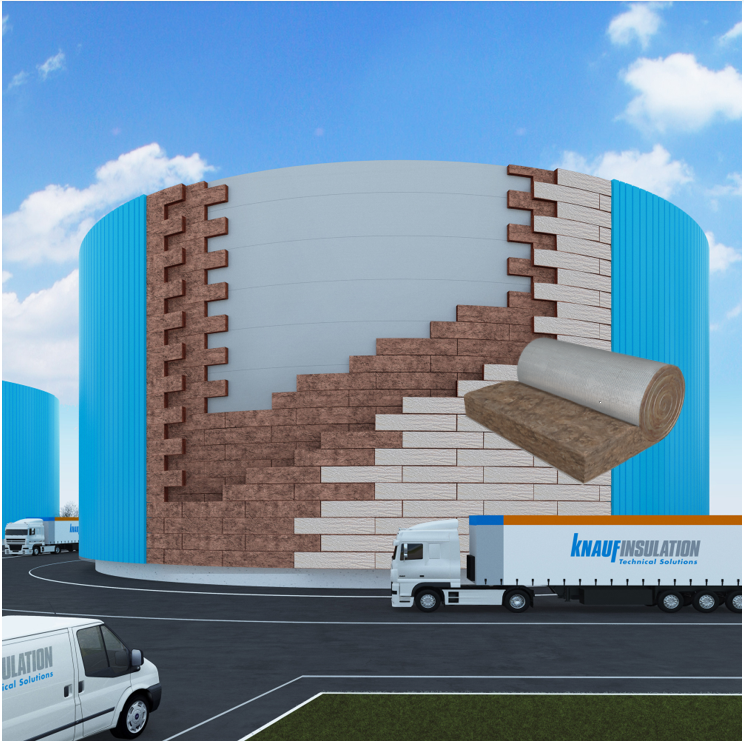

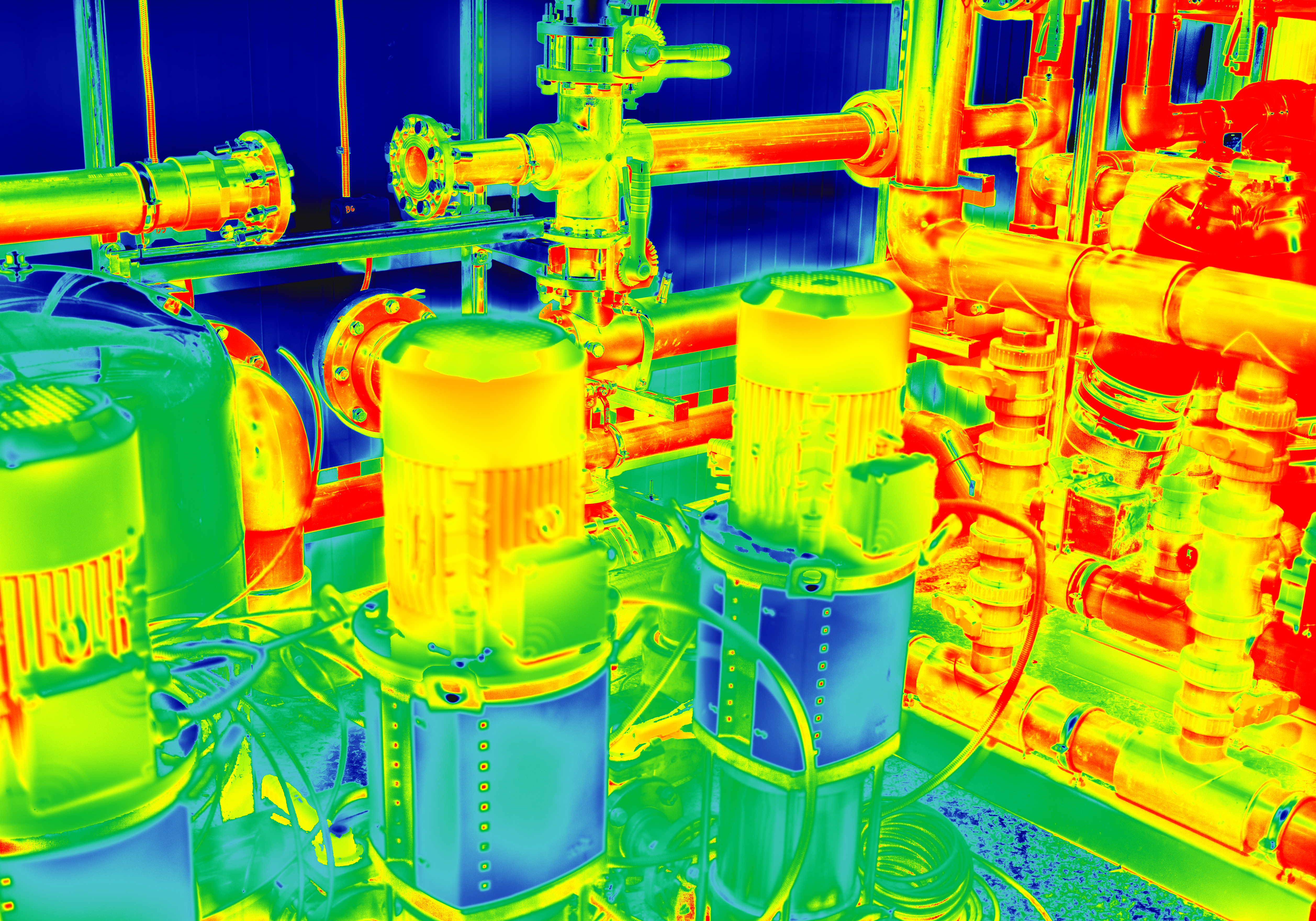

Better choice for industry

The ever-growing demand for sustainable solutions motivated us to speed up the expansion of products available with ECOSE® Technology in the range of our Technical Solutions. First, a few years ago, we introduced solutions with ECOSE® Technology for HVAC (Thermo-teK), and it was an instant success. Not long afterwards we introduced technical solutions with HVAC technology for industry (Power-teK), shipbuilding (Sea-teK) and solutions for passive fire protection (Fire-teK).

Today our full range of Technical Solutions, rock and glass mineral wool, is available with ECOSE® Technology. It offers our partners and clients its outstanding performance and provides a much sought after planet-friendly alternative. In this way we are now, together, creating a better future for our planet and the generations to come.